Benefits & Features

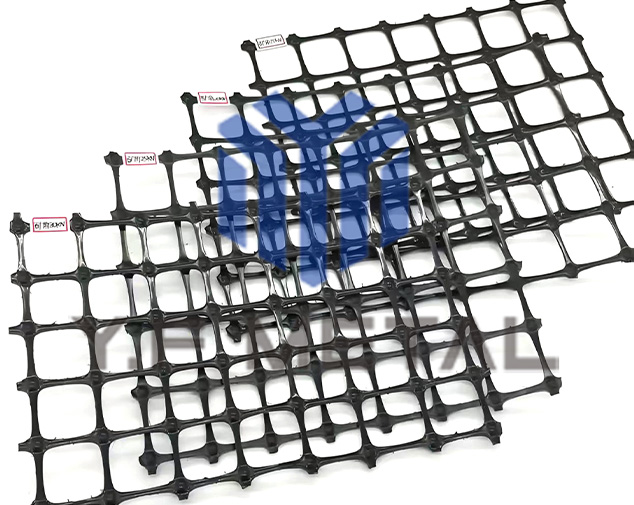

Mining plastic mesh is a support material for underground coal mines made from polypropylene (PP) plastic and special additives, using a biaxial stretching process and flame-retardant and antistatic technologies. It is primarily used for false roof support in mining face applications and rock bolt tunnel support, replacing traditional materials such as metal mesh, wood, and bamboo rakes.

Product Features:

1. Compared to bamboo rakes and metal mesh, this product features a smaller and lighter roll of plastic mesh. An 8-square-meter roll of plastic mesh weighs only approximately 4 kg, while metal mesh of the same area weighs 25.5 kg. Laying is easy and labor-intensive.

2. Its mesh openings are smaller than metal mesh, resulting in a larger effective shielding area, greater safety, better roof control, and improved coal quality management.

3. Plastic mesh is acid- and alkali-resistant, and corrosion-resistant. Its performance remains essentially unchanged after one year of underground burial, whereas metal mesh suffers from significant corrosion, significantly reducing its strength. Benefits:

1. By laying plastic protective nets, the stability of the surrounding rock mass in the harbor channel is improved, preventing roadway wall spalling, rock leakage, and roof collapse, thereby improving roadway safety and reducing accidents.

2. It reduces roadway ventilation resistance and conserves energy.

3. Plastic nets are lightweight, acid- and alkali-resistant, inexpensive, and easy to lay.