Benefits & Features

Rigging refers to the equipment used with ropes and cables, such as hooks, slackjacks, cleats, shackles, etc., collectively known as rigging. Some also classify ropes and cables as rigging. Rigging is primarily divided into two categories: metal rigging and synthetic fiber rigging. It is a general term for masts, yards (spades), yards (sail booms), gaffs, and all ropes, chains, and the equipment used to operate them.

Classification and Application:

Rigging is primarily divided into two categories: metal rigging and synthetic fiber rigging.

Metal rigging primarily includes wire rope slings, chain slings, shackles, hooks, slings (clamps), and magnetic slings.

Synthetic fiber rigging primarily includes ropes and belts made from nylon, polypropylene, polyester, and high-strength, high-modulus polyethylene fibers.

Application:

Rigging includes applications such as D-rings, safety hooks, snap hooks, slings, linking double-ring buckles, and American-style eyebolts. Rigging is widely used in key industries such as ports, power generation, steel, shipbuilding, petrochemicals, mining, railways, construction, metallurgy, automobile manufacturing, construction machinery, papermaking machinery, industrial control, logistics, heavy-lift transport, pipeline support, maritime salvage, marine engineering, airport construction, bridges, aviation, aerospace, and stadiums.

Common Rigging:

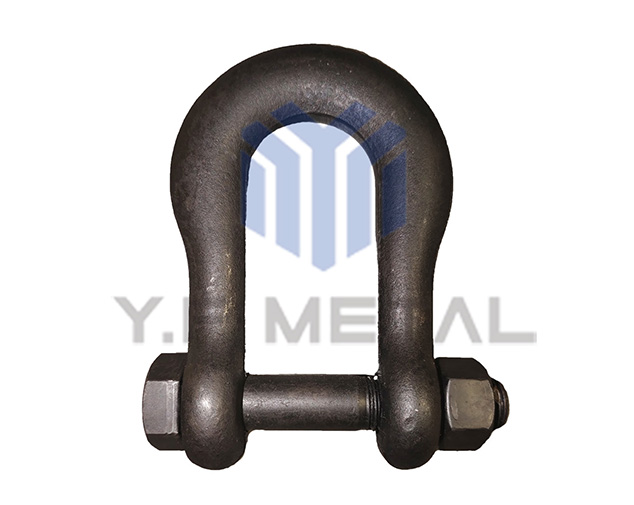

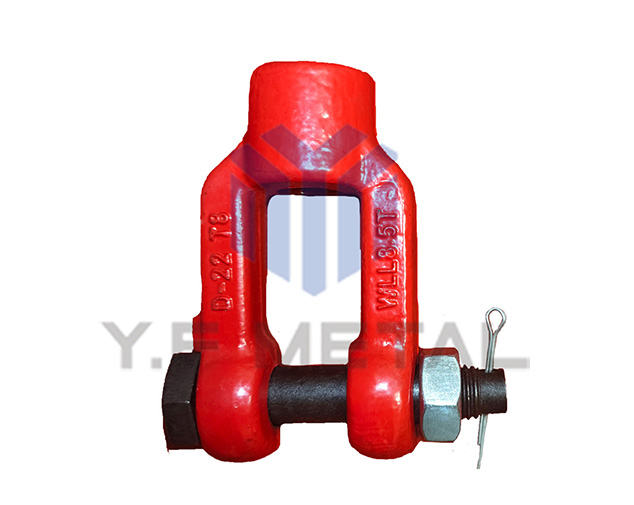

Shackles:

A shackle is a removable, ring-shaped metal component used to connect various rope eyelets, chain links, and other rigging equipment. A shackle consists of a body and a crossbar. Some crossbars have threads, while others have pins. Common types include straight and round shackles. Shackles are often named according to their intended use. For example, a shackle used on an anchor rod is called an anchor shackle; a shackle used on an anchor chain is called an anchor chain shackle; and a shackle used on a rope end is called a rope end shackle.

Hooks:

A hook is a tool made of steel used to suspend cargo or equipment. It consists of a handle, a back hook, and a tip. Depending on the orientation of the eye on the hook handle, hooks are classified as front hooks and side hooks. The tip of a front hook is perpendicular to the plane of the eye on the hook handle, while the tip of a side hook is aligned with the eye on the hook handle. Ordinary cargo hooks often use side hooks with a twist.

Hook Usage Precautions: When using a hook, the force should be concentrated on the center of the hook back to avoid breaking the hook. Hooks are weaker than shackles of the same diameter. When lifting heavy objects, shackles should be used instead to prevent the hook from straightening and breaking.

Chain:

Chain is a chain consisting of non-stop links. It is commonly used on ships as rudder chains, cargo short chains, tonnage chains, and adjusting links for safety cables. It is also used for pulling and lashing. Chain size is expressed by the diameter of the links in millimeters (mm). The weight can be calculated by the weight per meter of length.

When using a chain, the links should be aligned to avoid lateral forces. Avoid sudden force to prevent the chain from breaking. Chains should be regularly inspected and maintained to maintain good technical condition. The contact areas between chain links and between chain links and shackles are prone to wear and rust. Pay attention to the extent of wear and rust. If the wear and rust exceeds 1/10 of the original diameter, the chain should not be used. Also, check the chain for cracks. Don’t just inspect it visually; use a hammer to tap each link, listening for a crisp, resonant sound.

To remove rust from chain chains, it’s best to use a fire impact method. Heating the chain links expands them, loosening the rust. Impacting the links against each other can effectively remove the rust and eliminate small cracks. After rust removal, the chain should be oiled to prevent rust and minimize damage. Precautions:

1. Do not use damaged rigging.

2. Do not twist or twist rigging during lifting.

3. Do not allow rigging to become tangled.

4. Avoid tearing seams or overloading rigging.

5. Do not drag rigging when moving it.

6. Avoid forcibly pulling or jarring the load.

7. Inspect each rigging piece before each use.

8. Polyester is resistant to inorganic acids but is susceptible to damage from organic acids.

9. Polypropylene is suitable for use in areas most resistant to chemicals.

10. Nylon is resistant to inorganic acids but is susceptible to damage from organic acids.

11. Nylon can lose up to 15% of its strength when exposed to moisture.

12. If rigging is likely to be contaminated by chemicals or used at high temperatures, consult the supplier for advice.